How a collaboration between Purina and Dairy Foods delivered huge value

A project like this can't be accomplished without the help of people across the Land O'Lakes enterprise

At Land O’Lakes, Inc., we’re always looking for ways to drive value added products. And sometimes that growth comes with capacity challenges. This means we have to challenge the status quo, reach across business units and make changes to the way things are done.

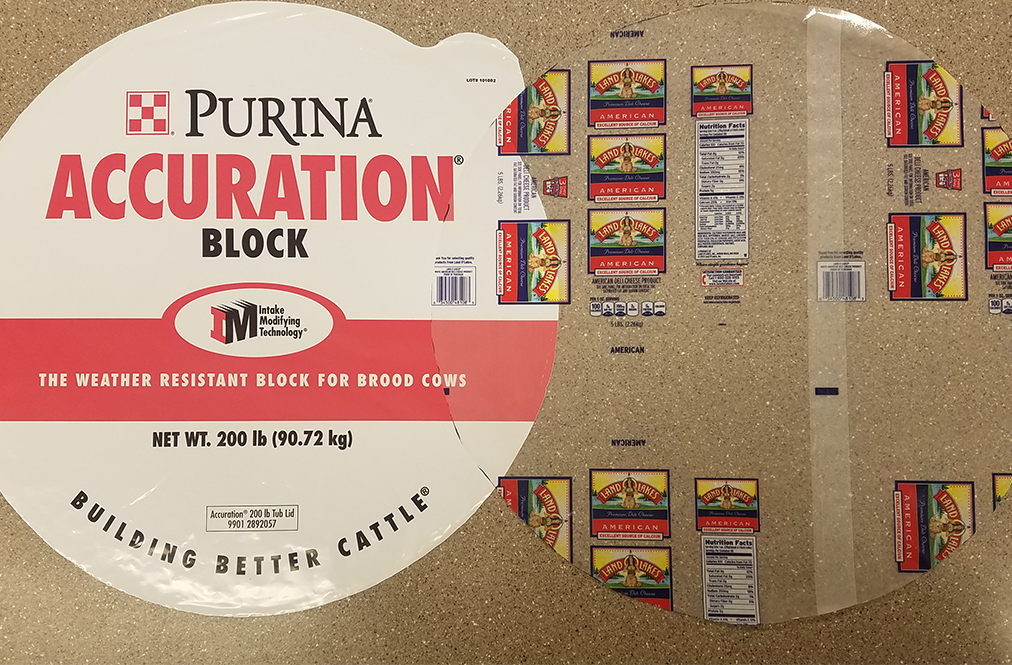

The projected growth of Purina® Accuration® Block was creating challenges for Anthony Robinson, associate marketing manager for cattle, and his team.

“Producers really like the convenience and Intake Modifying Technology®,” he says. “But we were on a demand trajectory that would outstrip capacity.”

Accuration® Block, a self-fed, high-fat protein supplement, is a proprietary and core part of Purina’s All Seasons™ Cattle Nutrition Program. Profit margin and volume for the Accuration® Block product line increased by double digits in both 2015 and 2016 in operations that have shared assets with other products. It became apparent that eventually we wouldn’t be able to make Accuration® Blocks fast enough to meet demand.

There are different ways to solve this problem. One solution is to build a new production plant. But that would require lots of money and time. Another solution is to look at the production process to see if it can be shortened without sacrificing quality.

“This product is a critical growth platform for the Purina Cattle business,” says Anthony. “We couldn’t mess this up.”

There had to be a way to increase production without investing in a new plant. That’s when Anthony went to R&D to see if they had any ideas.

How to increase production

As Mike Gabriel, R&D packaging engineer, Ben Danenberg, R&D packaging manager, and Mike Burr, process research director, found out, ideas and solutions can come from the most unexpected places.

The three of them were meeting at the Purina Animal Nutrition Center in 2015 to review different types of packaging for cattle feed when they started talking about a challenge raised by feed plant employees. The process for putting covers on the 225-pound tubs of Purina® Accuration® Block supplement was slowing down production. After the tub is filled with product, it heats up to help cure—or harden—the product. If you put the cover on before the product is cured, the cover won’t stick to the product surface.

“After the tub is filled with product, it’s taken off the line and stored on pallets for 12 to 24 hours to cure,” explains Mike Gabriel. “Once the product has cured, it’s removed from storage where it’s sprayed with liquid molasses. The molasses acts as a glue for the cover.”

After learning about the demand issue from Anthony, the R&D trio were determined to find a way to shorten production of Accuration Block®. Ideas flew back and forth until they settled on a possible solution: processed cheese wrap. Specifically, the film that’s used on LAND O LAKES® Deli American.

“Deli American is packed in a material with a wax coating that comes into contact with the cheese’s surface,” says Mike. “It protects the product and acts as a moisture barrier.”

Testing and tweaking

With the idea in mind and support from Anthony and the business to test it, a phone call to our dairy plant in Spencer, Wis., got things moving. As the manufacturer of Deli American, Spencer was the perfect place to get film to test R&D’s idea.

“Right off the bat, the process looked like it had potential,” says Mike. “The cover could be applied right away, without the product needing to set. It peeled off nicely and didn’t tear. We thought we were on to something.”

The trio began working to make changes that would optimize the packaging. The next step was to test the new covers at the feed plant in Rosenberg, Texas. They needed to ensure that the process could be done at the plant.

“During our trial at Rosenberg, we noticed different handling practices,” says Mike.

At the Kansas City plant, tubs were moved one-by-one on and off the pallets. The Rosenberg plant clamps four tubs together before moving them on or off a pallet. As it turns out, clamping tubs together loosens the covers from the tubs.

“We worked with Bemis to change the structure of the covers so they wouldn’t release when the tubs were clamped together,” says Mike.

True collaboration

In all, R&D ran four trials at the Rosenberg plant before settling on the covers and production process that will be fully implemented this fall. Instead of taking just over six hours and 45 minutes to complete 1,320 tubs, it will now only take five hours. That’s a 42 percent increase in capacity.

With the introduction of a new product line extension, the Accuration® Hi-Fat Block, the business continues to see results. Purina has steadily increased the number of “ship to” locations selling Accuration® Block by nearly 80.

“This is huge,” says Anthony. “Not only did we not have to build a new plant to increase production, but we were able to collaborate across the business to help with process improvement.”

A project like this can’t be accomplished without the help of people across the Land O’Lakes enterprise. Folks in R&D, Sourcing, Marketing and the Rosenberg feed plant worked together to identify the problem, come up with a solution and provide valuable input along the way.

This is the kind of “out-of-the-box” thinking that will help us remain competitive in our rapidly changing industry.